SAWKILL + THE VIRGIN FORESTS

Seeing old lumber from hundreds of demolished buildings, primarily in the Northeast, we’ve discovered the species that were used in different eras and followed their paths back to their old-growth forests. Some of the wood we’re now reclaiming was in the virgin forests, growing on American soil before Christopher Columbus arrived. Native Americans had long been clearing land with fire for hunting and farming, and venerating the spirits of trees, especially the eastern white pine, or Tree of Peace .

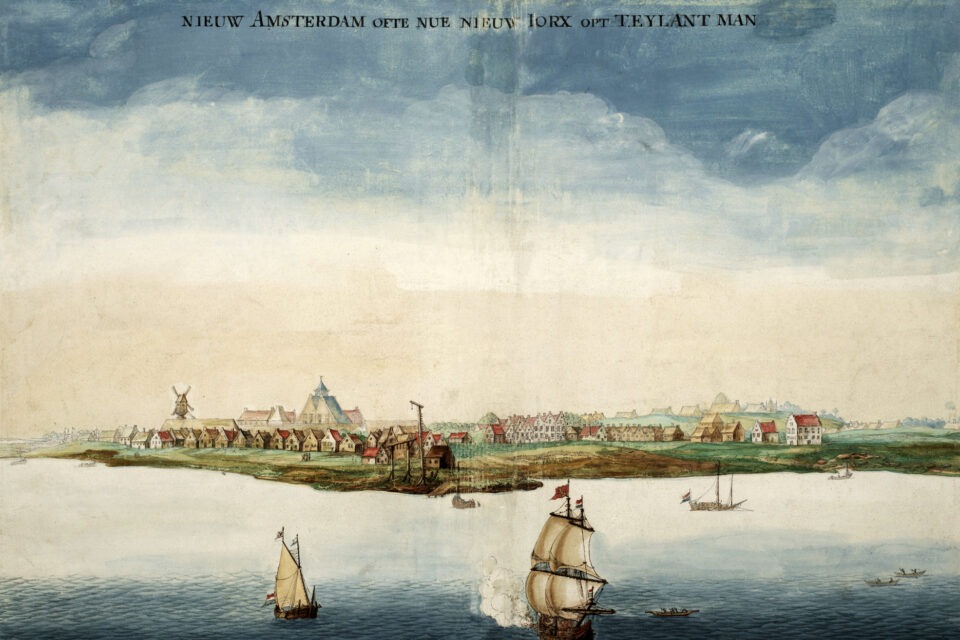

It’s hard to overestimate the role of the forests in everyday life in North America, but, for the first Europeans, wood was of little importance to their hopes and dreams. The Pilgrims of 1620 sailed to Plymouth to gain religious freedom. The early Dutch explorers were looking for a passage to another place, farther east. The English who settled Jamestown, Virginia, in 1607 were in search of financial return, preferably gold. What they all found, revered, and then exploited was trees. The first arrivals witnessed the virgin forests rising out of the sea as they came closer to shore. In his journal of Henry Hudson’s 1609 voyage, Robert Juet admired the trees on the banks of the river that would be named for the explorer: “goodly Oakes, and Wal- nut trees, and Chest-nut trees, Ewe trees, and trees of sweet wood in great abundance.” The forests were dense and, for the most part, impenetrable by horse.

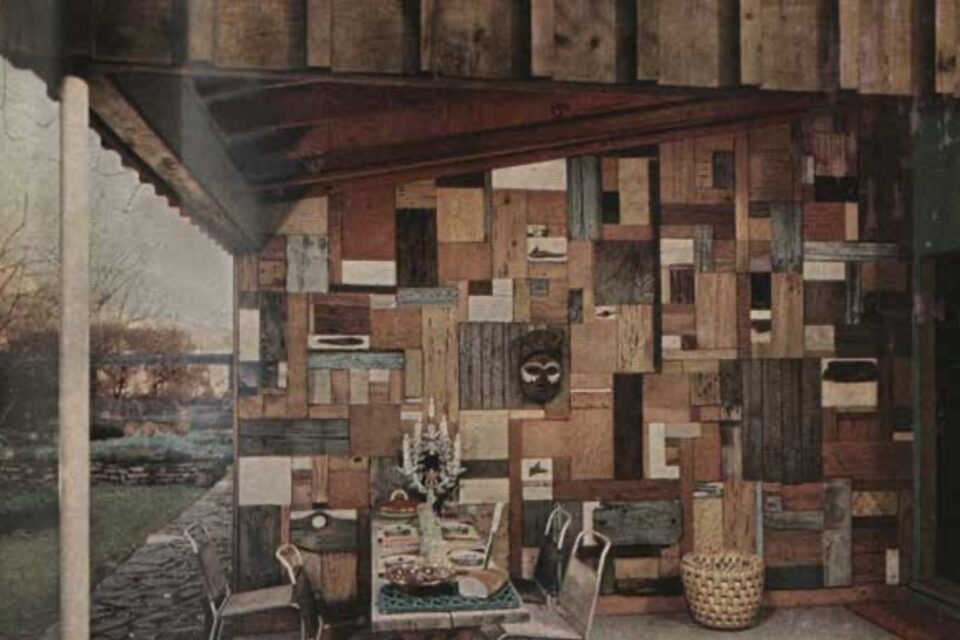

For these Dutch settlers in New Amsterdam, they offered the greatest supply of timber they’d ever seen. In the 1620s, the advanced Dutch sawmills—technology that helped drive the Dutch Golden Age—were deployed to an early logging site: the backwoods of Manhattan Island, where they constructed one of the continents first water-powered sawmill, located near today’s Central Park, along the Saw-kill (Dutch for “sawmill creek”), which is the origin of the companies name. Many of the old buildings standing in New York City, from where we harvest lumber, are framed, it’s a wonder to discover, with lumber that’s old enough to have grown at the site when it was a virgin forest.