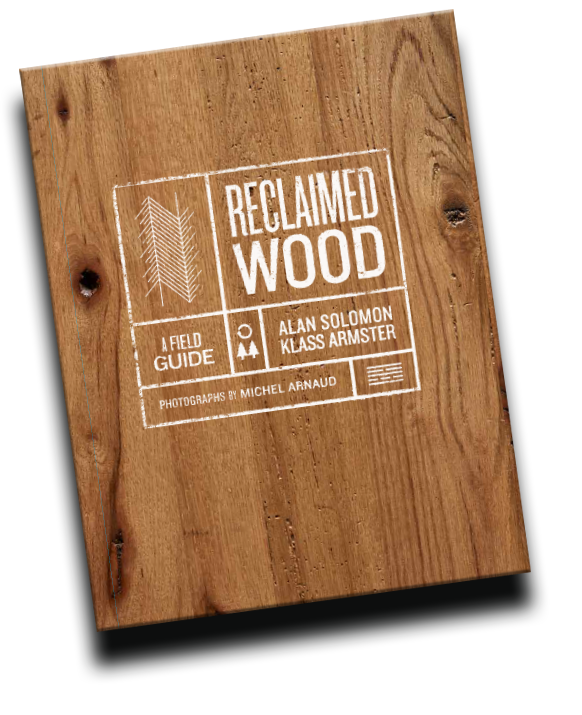

Families are smaller and company boards hold remote video conferences today, but the large table, especially one from reclaimed wood, is far from a thing of the past. Making one involves the same steps as any table (with a metal base), but any difficulties are often amplified with size. This may include potential for wood movement and end splits, added production capacity, especially for clamp and glue up and building a table base that is adequately stable.

Families are smaller and company boards hold remote video conferences today, but the large table, especially one from reclaimed wood, is far from a thing of the past. Making one involves the same steps as any table (with a metal base), but any difficulties are often amplified with size. This may include potential for wood movement and end splits, added production capacity, especially for clamp and glue up and building a table base that is adequately stable.

The above table for a local downtown BID includes an industrial style i-beam base with a 4′ x 10′ table top from reclaimed native softwoods. The woods have been sanded to reveal the figure without removing all of the aged patina and other characters marks.